Thang máy Tải Khách dòng PE

TNE Passenger Elevators – PE Series is the standard and optimal solution for the buildings up to 15 floors, speed 60 - 105 m/min and the standard loads : 320 kg – 1,000 kg which are suitable for the privated house, mixed-use spaces, office buildings, hotels, social residences, schools. etc…

Thien Nam Elevators are manufactured in compliance with TCVN 6396-20: 2017; TCVN 6396-50: 2017; QCVN 02-2019 ensuring optimal performance in Vietnam’s hot and humid climate. The system is designed to operate reliably at ambient temperatures of up to 40°C and daily average humidity levels of up to 95%.

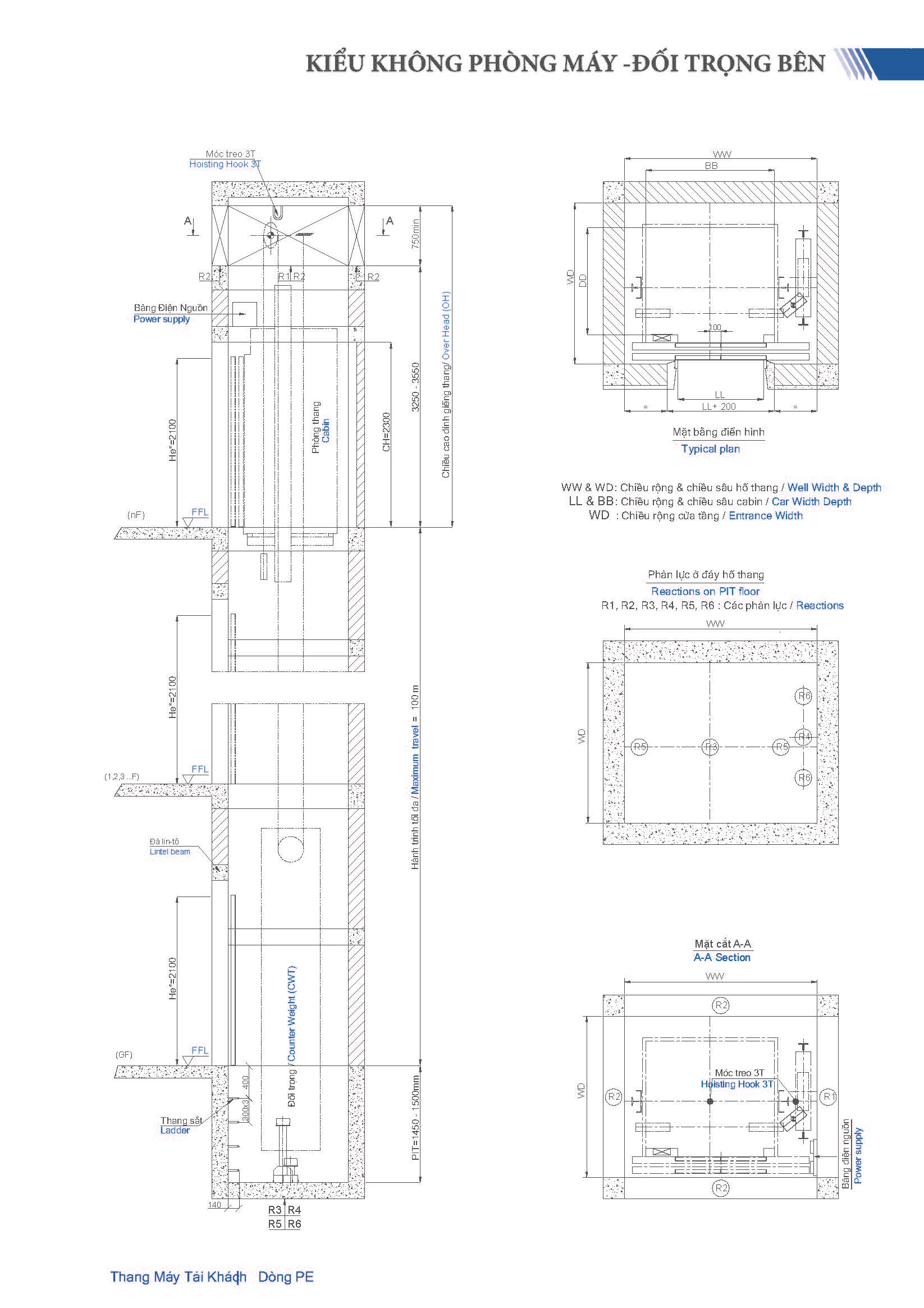

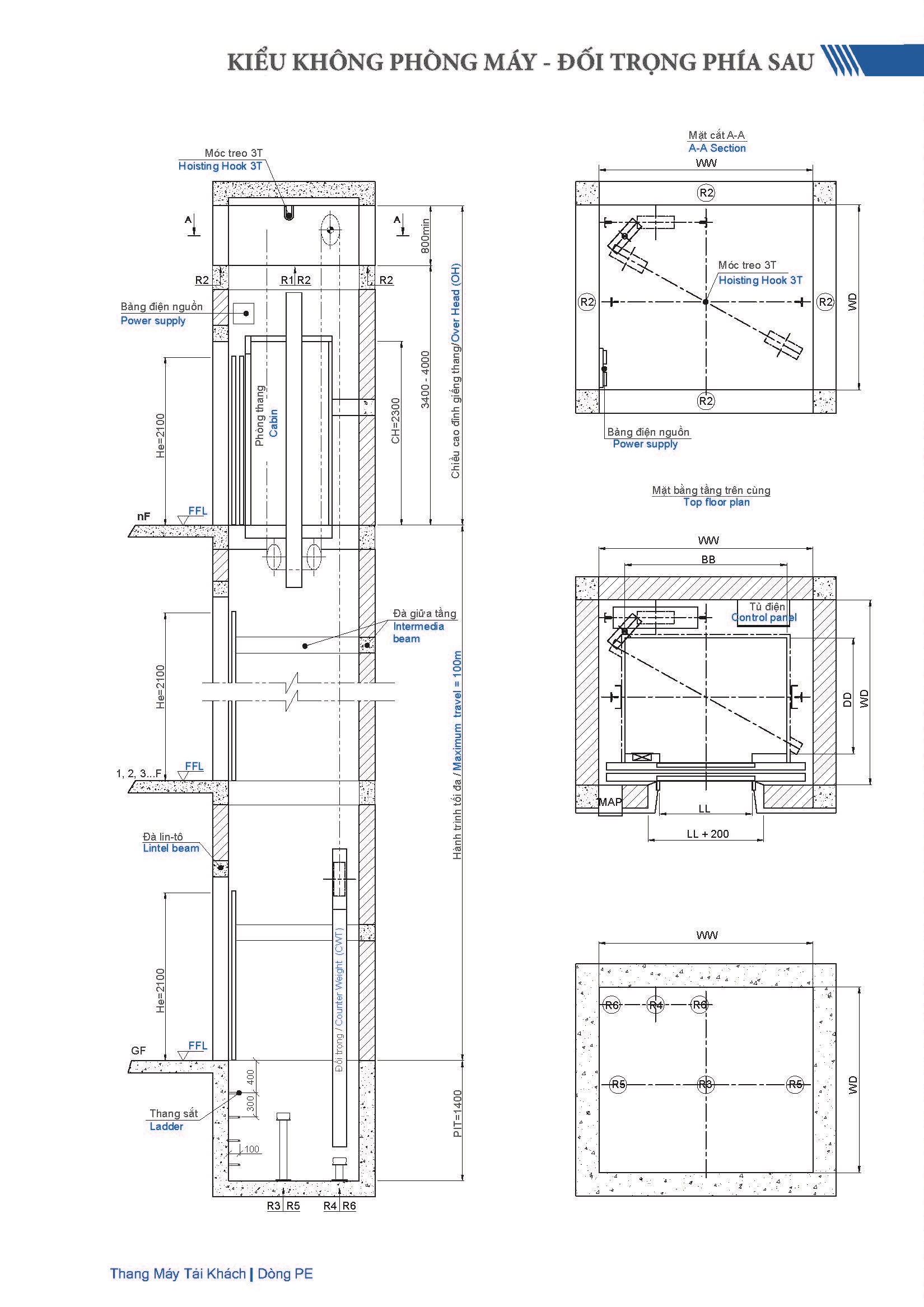

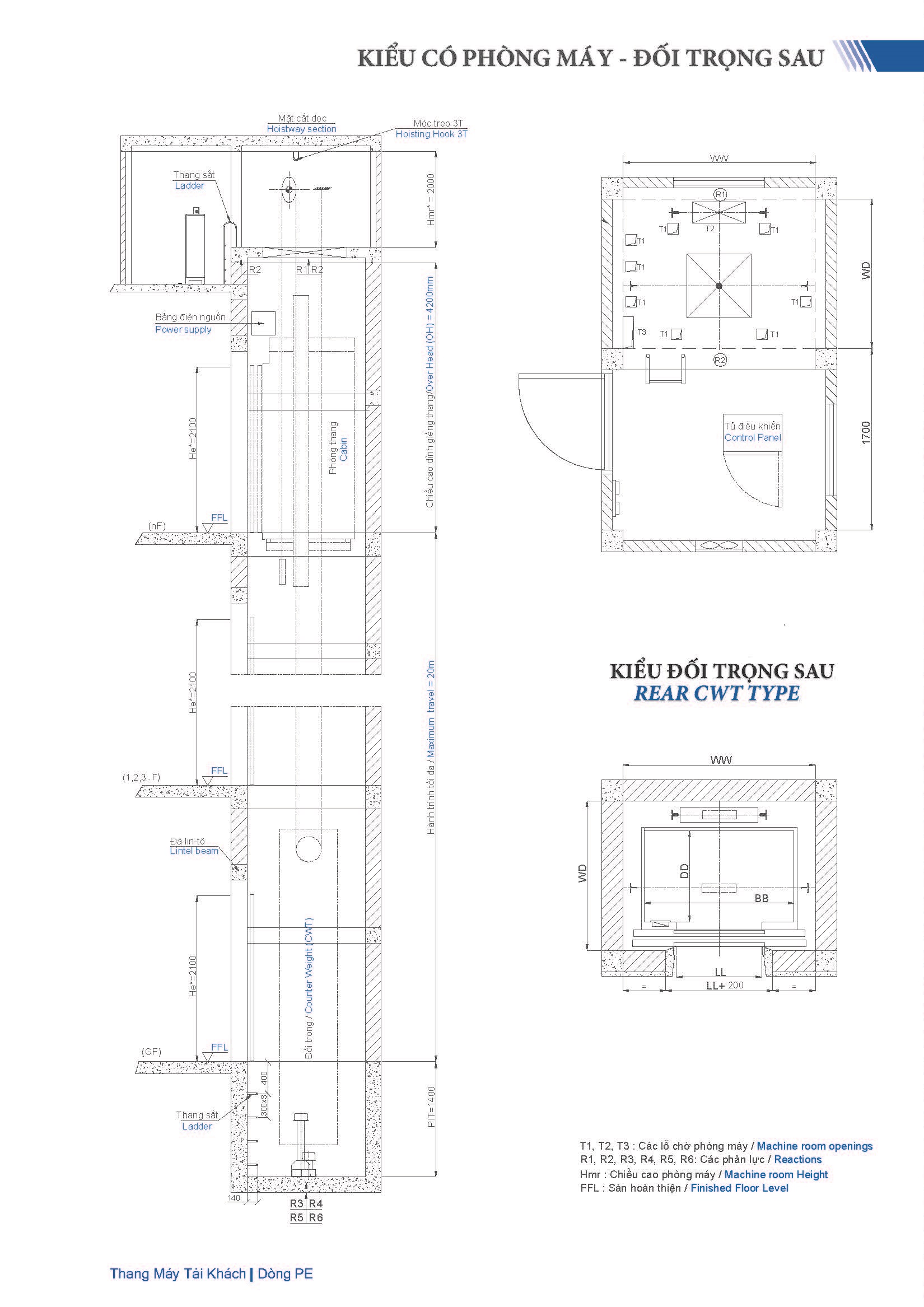

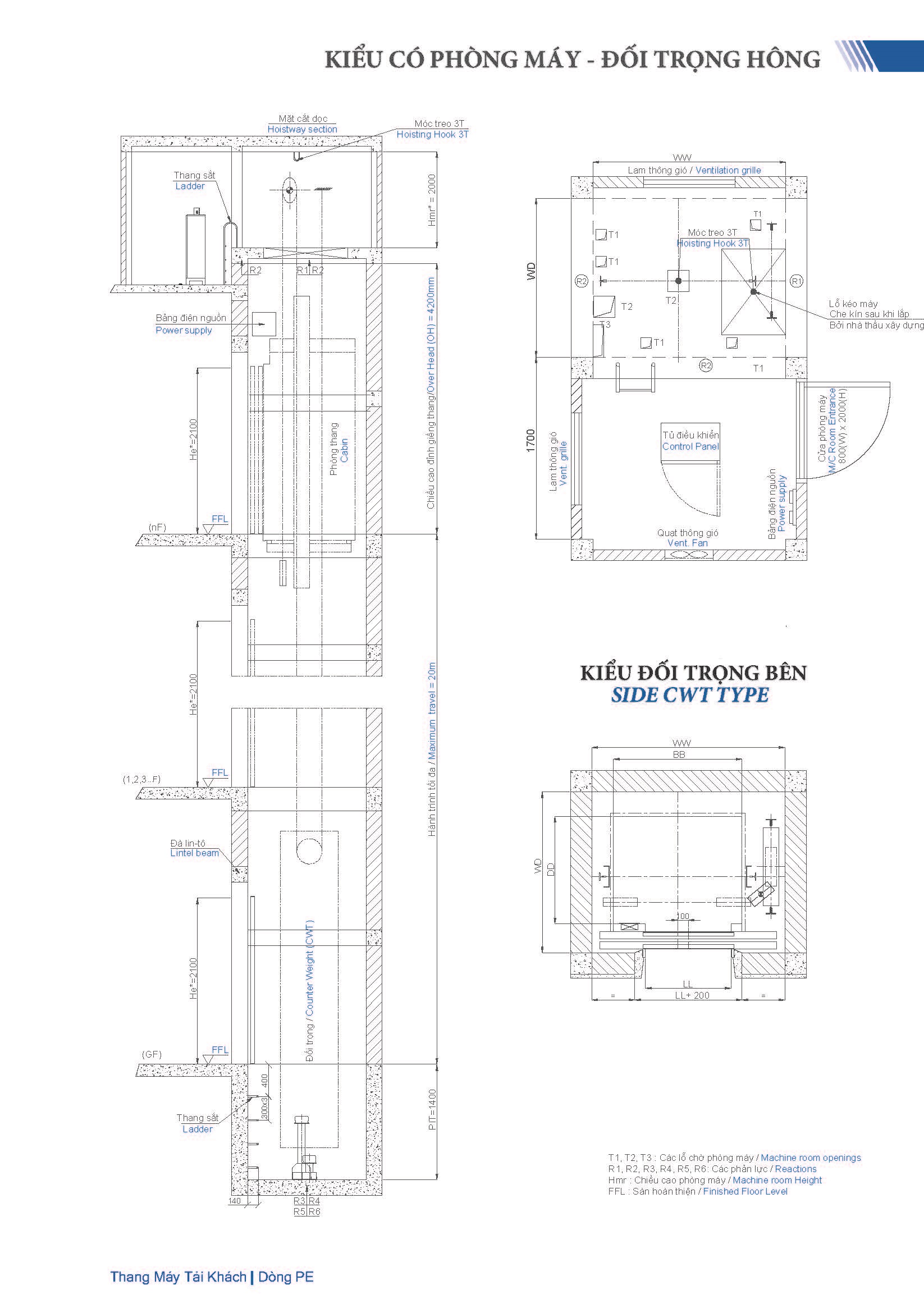

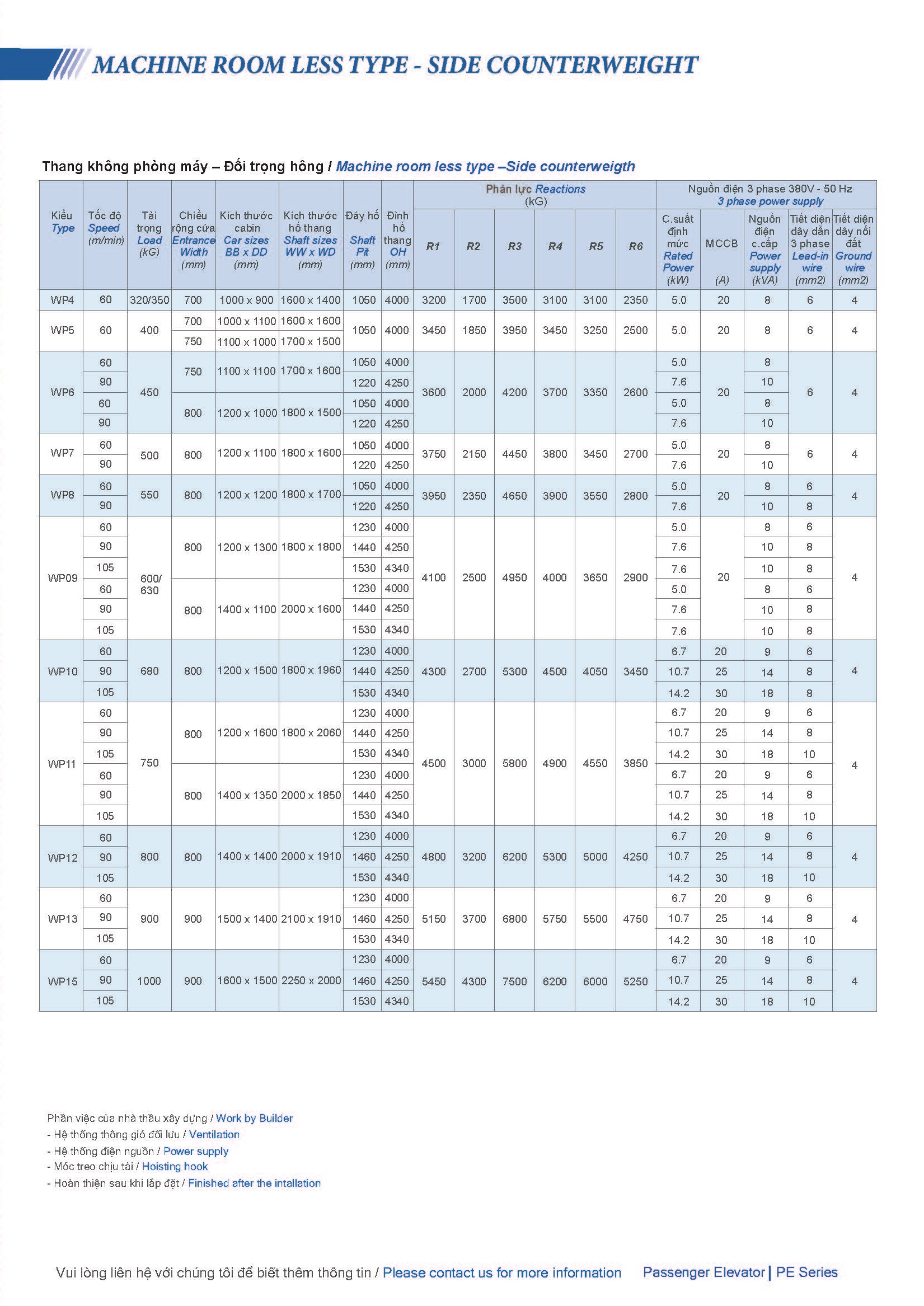

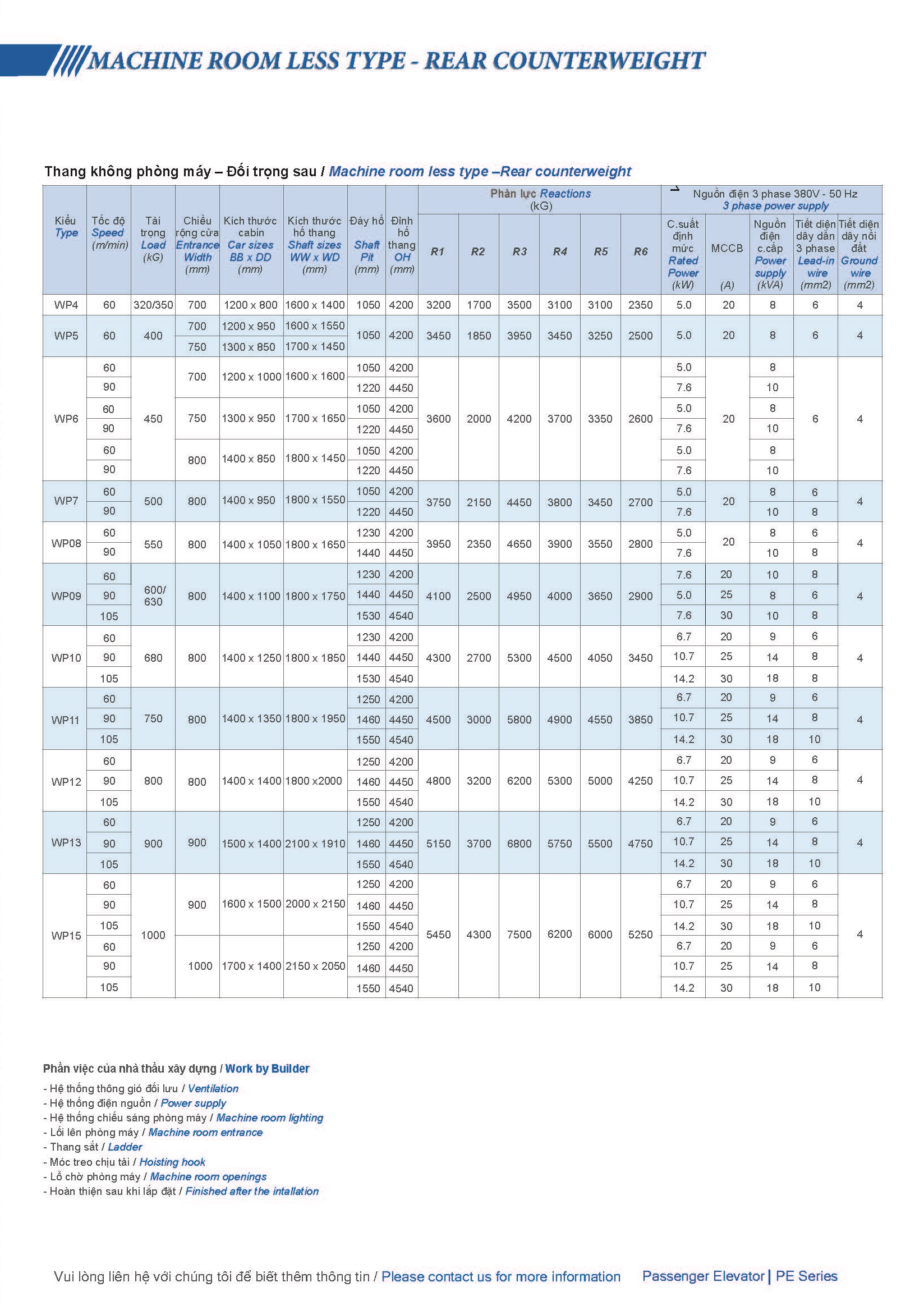

The PE Series is compactly designed with optimized PIT and overhead dimensions, allowing flexible machine placement. Thanks to standardized production processes, these elevators offer high reliability while keeping manufacturing costs competitive. The cabin designs are elegant and well-coordinated, making it easy for customers to choose models that best suit their building aesthetics. For villas or buildings with limited roof space, machine room-less options provide an ideal solution.

TNE utilizes permanent magnet synchronous motors (PMSM) in both machine room and machine room-less models, enhancing energy efficiency. All motors come with a minimum 12-month warranty. Another notable advantage of the PE Series is its fast delivery time, allowing projects to stay on schedule—even with urgent deadlines.

Operation system

- Full Selective Collective operation: during operation, lift serves calls from the landings in moving direction, service calls from the landings in opposite direction afterwards. When lift arrive at landing, illumination of corresponding button will be off

- Attendant operation: lift can be changed from normal operation mode to attendant operation mode by an “Priority Switch” located on Car Operating Panel (COP). During this operation, lift only serves calls from car inside

Car door safety device

This device makes doors open automatically while closing to aim preventing passengers or other objects knocked against doors

Automatic door open/ close time adjustment

Door open/close times are automatically adjusted depending on numbers of hall or car calls in order to increase operating efficiency

Over load

When car load exceeds rated load, indicator is on, a buzzer sounded and lift is prevented from starting

Arrival announcement

Indicator displays the landing floor, a buzzer sounded

Car fan and light turn-off Automatically

For energy saving, car fan and light turn off automatically in case there is no hall call or car call

Automatic Rescue Device

In case of power failure, lift will be sent to the nearest floor by DC power of battery, door open for passenger getting off

Emergency light

In case of power failure, emergency light on car ceiling turned on automatically

Intercom system

In case of emergency, press the “Emergency button” located on car operating panel to communicate with responsible persons

Indicators

Matrix indication lights with orange color to ease for elderly, poor eyesight and eye-color sick people, then also indicating the present status of elevator in Vietnamese/ English/ Japanese/ Chinese

Automatic Re-leveling

The elevator will be automatically to get leveling with the landing floor when sudden changing loads

Car call cancelation

If making wrong calls, the passengers can cancel the calls inside the car

Bypass outside calls

If the hall buttons damaged, then this function can bypass the outside calls. (Error of the sticky buttons)

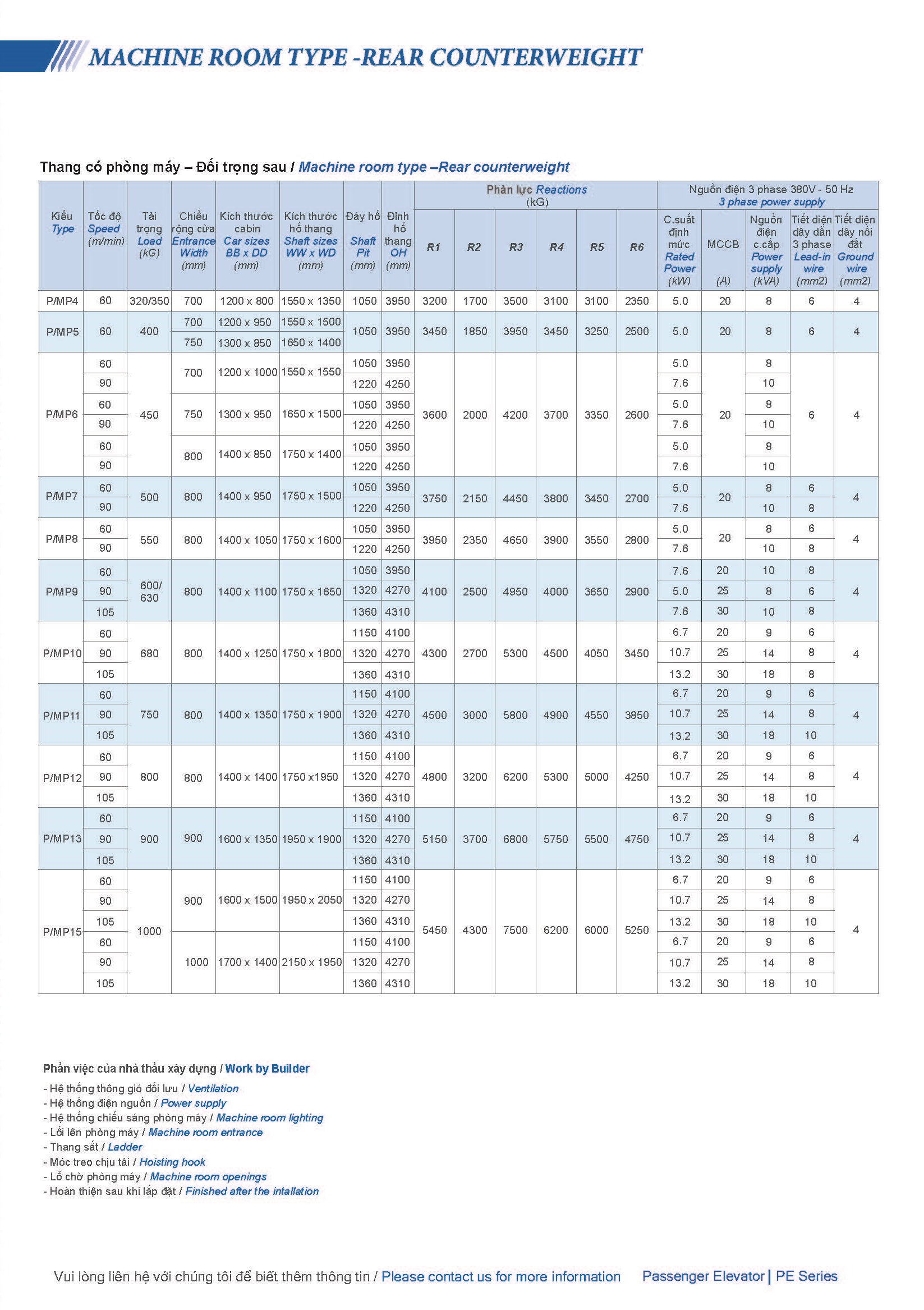

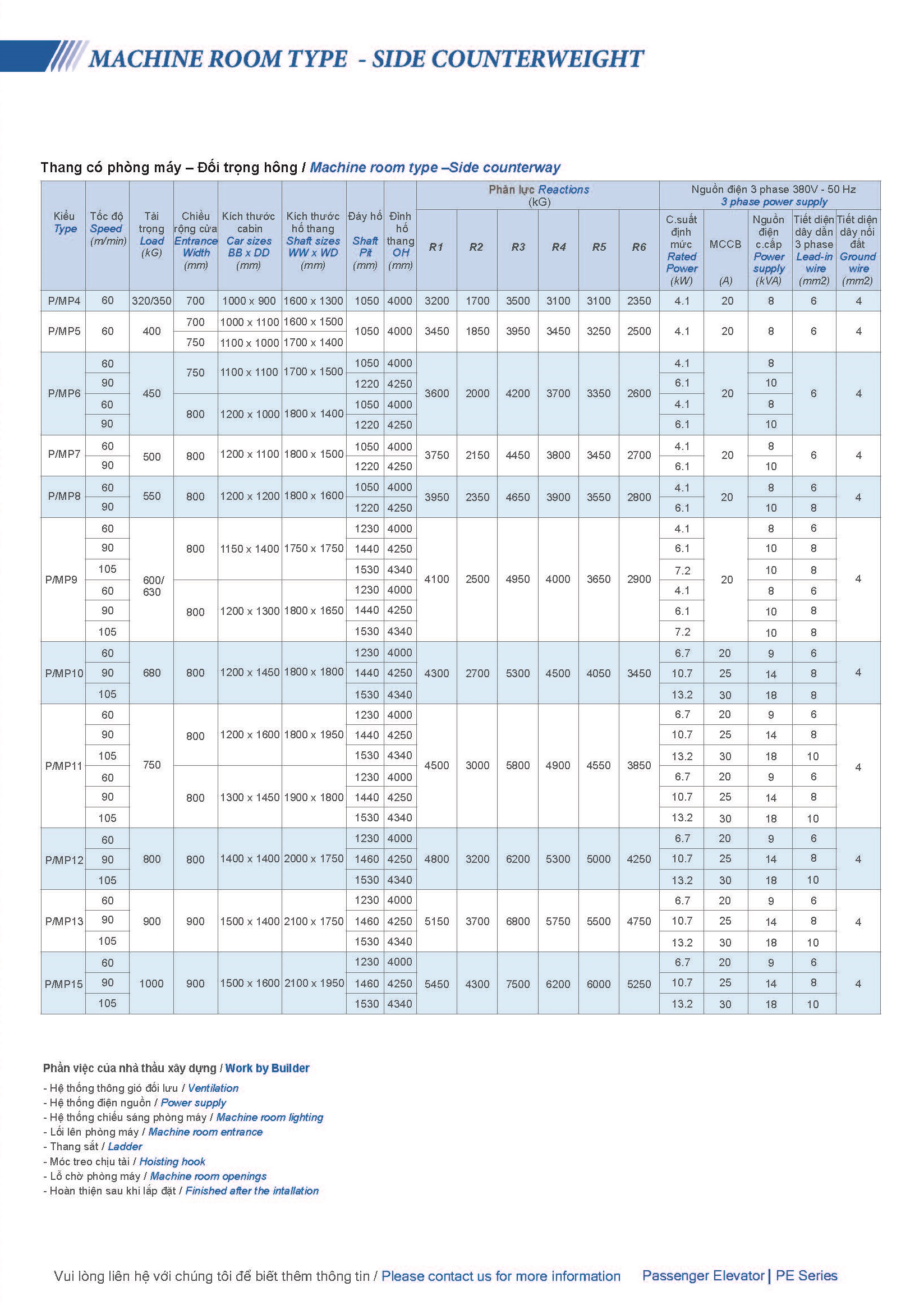

Elevator with machine room

Main control circuit: SOC210 with MCU: ATMEL + Tl 32 bits. Signal transmission method: serial signal transmission using CANbus transmission line. The system stores the last 50 errors including the time of error occurrence. The function automatically checks the braking force of the main motor to ensure that the brake is always in good working condition. Monitoring the status of rescue batteries: making sure the backup batteries are always in good condition, ready for rescue activities when the power is out.

Elevator without machine room

Controller consists of 2 cabinets: the main cabinet is located inside the hoist way and the MAP cabinet is located in front of the top floor. Main control circuit: SOC210 with MCU: ATMEL + Tl 32 bits. Signal transmission method: serial signal transmission using CANbus transmission line. The system stores the last 50 errors including the time of error occurrence. The function automatically checks the braking force of the main motor to ensure that the brake is always in good working condition. Monitoring the status of rescue batteries: making sure the backup batteries are always in good condition, ready for rescue activities when the power is out. Monitoring the speed and direction of movement of the elevator from the MAP cabinet when rescuing the brakes by hand, can observe and determine when the elevator enter the open area on the floor. This capability helps to provide quick and effective safety assistance in the event of emergency rescue.

Machine room

1. Construction of the machine room in accordance with shop drawing provided by Thien Nam. The walls and the ceiling shall be finished with waterproof plaster. Door equipped with a lock.

2. Cutting openings to lift the equipment and roping, wiring from machine room to hoistway. Provision hoisting hook.

3. Corridor, stairway, ladder to the machine room should be unobstructed. Stairs should be equipped with handrails and 700mm minimum in width.

4. Ventilation: installing ventilation grilles, ventilation fans. The temperature of the machine room shall be below 40°C. The relative humidity should not exceed 90%monthly average and 95% daily average.

5. Lighting: setting natural lighting windows, fluorecent lamp and switch.

6. The machine room power - 01 Power supply panel: The power should be three-phases (380V - 50Hz) four-line and grounding. Power supply voltage variation doesnot exceed ±5%

Hoistway & landing doors

1. Contruction of an illuminated, ventilated, and waterproofed elevator hoistway, in accordance with shop drawing provided by Thien Nam. The tolerance of perpendicular line over the whole hoistway height must not exceed +25m.

2. Cutting openings for installing landing doors, hall buttons and indicators. Finish after installation.

3. Provision seperated beams if two or more connected elevators in one hoistway & safety seperated fence between the pits.

4. Water pipes, electrical wires… etc, must not be assembled inside hoistway.

5. Provision intermediate beams if oor height is over 2.600mm.

Special remarks

1. Provision all electric power for lighting, tools, welding...etc during installation and test operation.

2. Provision a secured area for storage of elevator equipment and material during installation.