Passenger Elevator

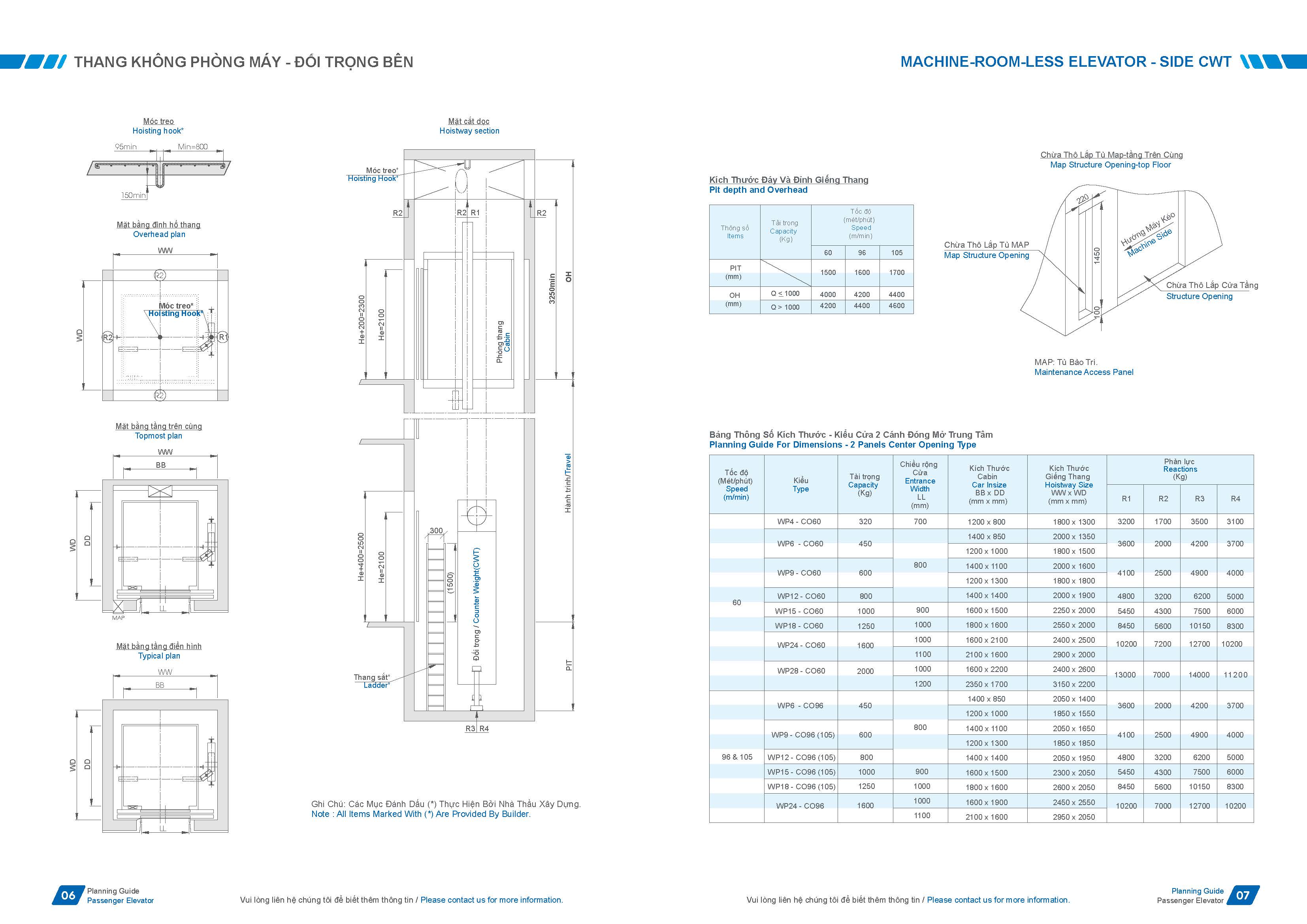

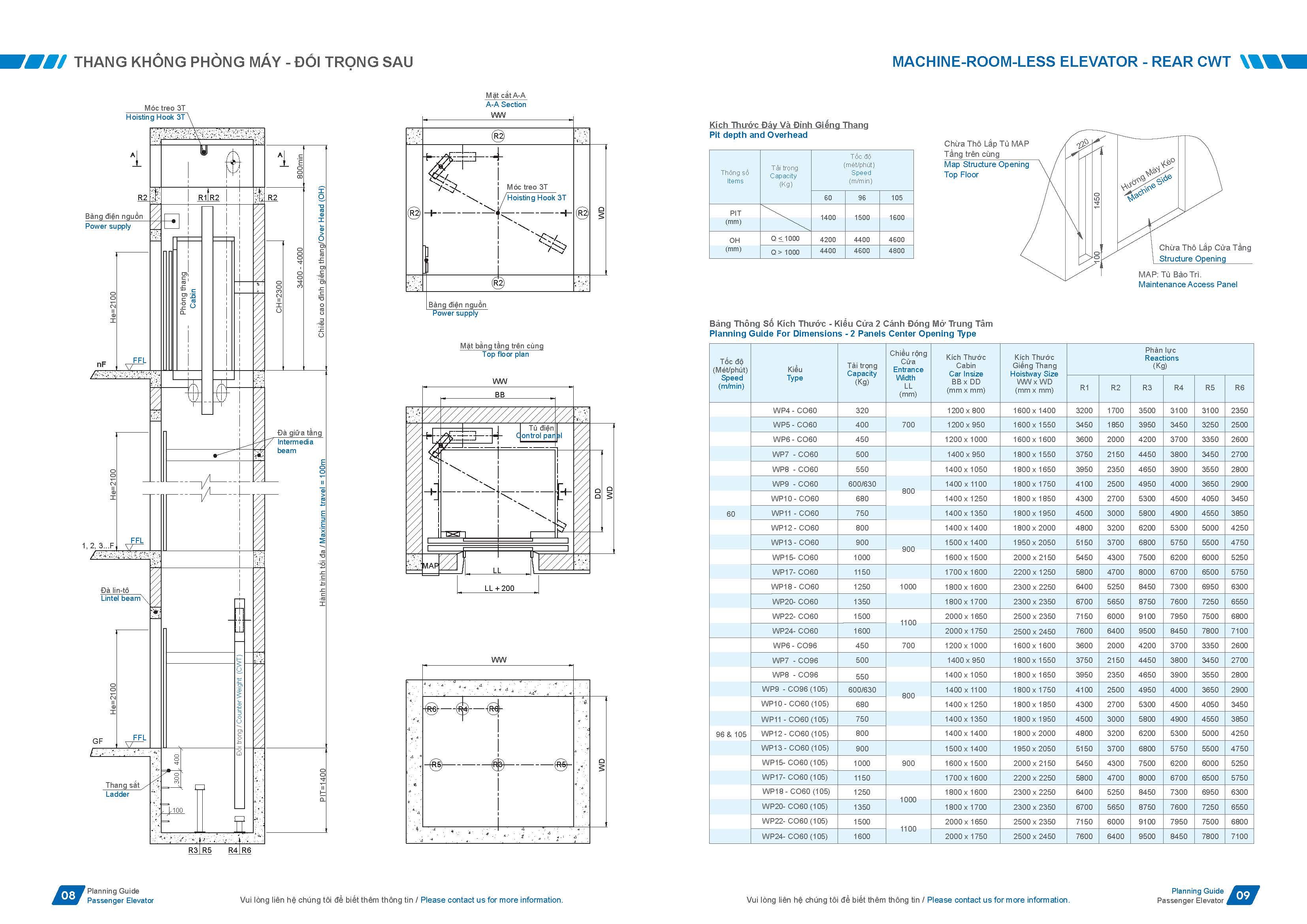

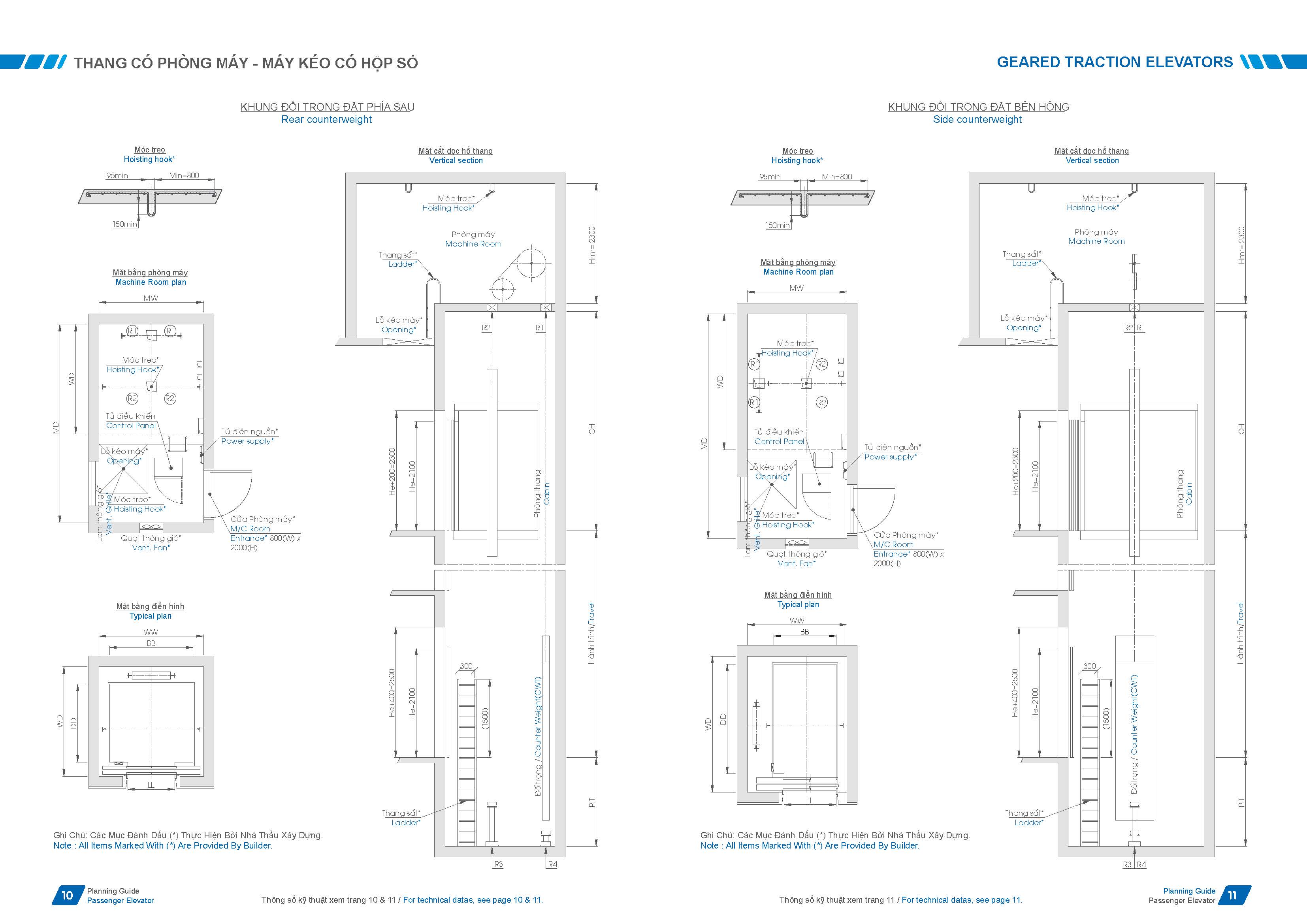

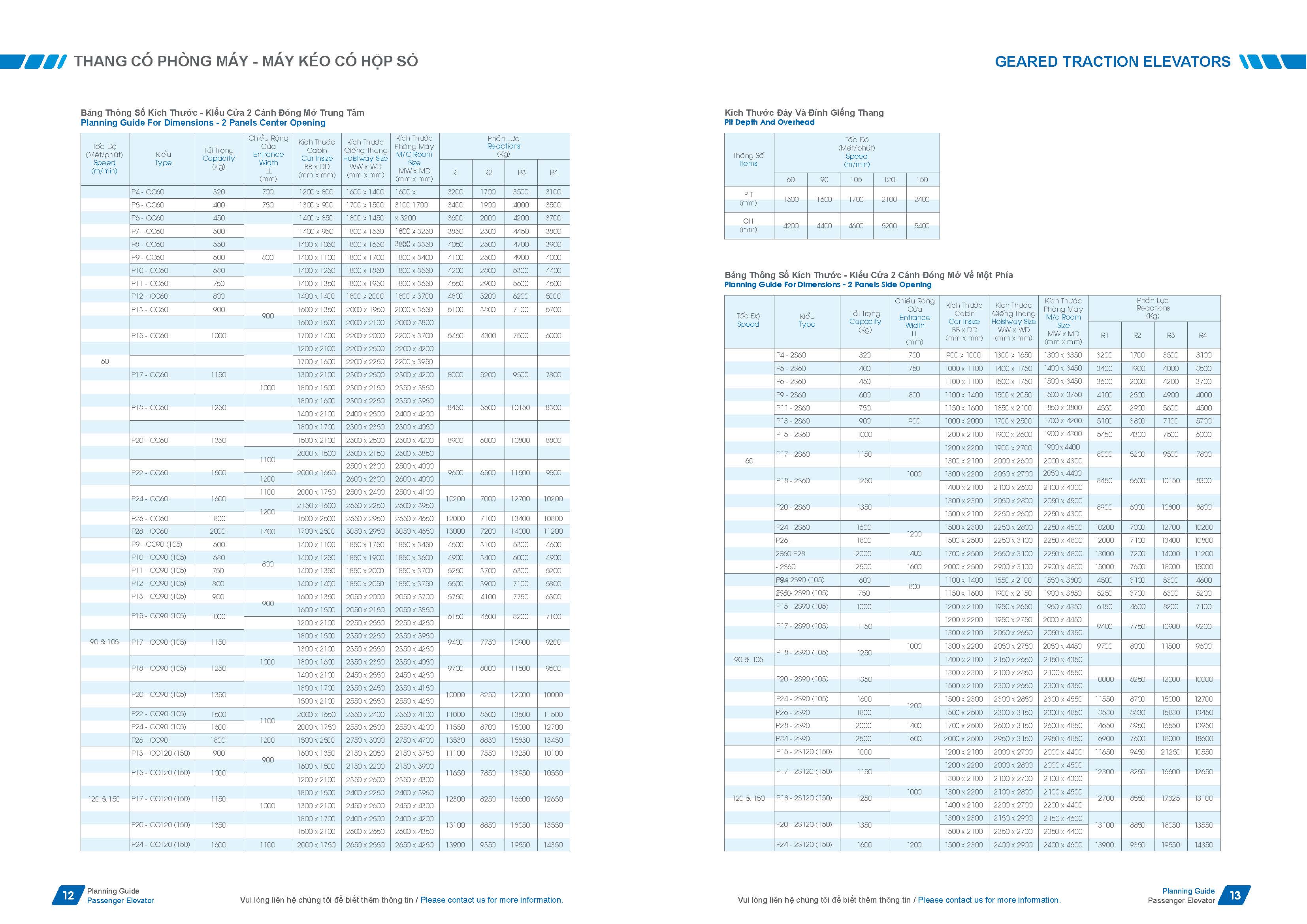

In order to supply to Architects, Investors informations about elevator’s designs, we introduce this catalogue with the most useful dimensions of Passenger Elevator’s hoist-ways that are suitable for low rise to medium rise projects (30 floors) with 2 types of door opening: CO – Center Opening and 2S – Side Opening.

If the building have many elevators, the group control of elevators, such as: Duplex, Triplex, Quattro, should be considered to the traffic calculation of the whole buildings. Please feel free to contact with us to get more advices.

Operation system

- Full Selective Collective operation: during operation, lift serves calls from the landings in moving direction, service calls from the landings in opposite direction afterwards. When lift arrive at landing, illumination of corresponding button will be off

- Attendant operation: lift can be changed from normal operation mode to attendant operation mode by an “Priority Switch” located on Car Operating Panel (COP). During this operation, lift only serves calls from car inside

Car door safety device

This device makes doors open automatically while closing to aim preventing passengers or other objects knocked against doors

Automatic door open/close time adjustment

Door open/close times are automatically adjusted depending on numbers of hall or car calls in order to increase operating efficiency

Over load

When car load exceeds rated load, indicator is on, a buzzer sounded and lift is prevented from starting

Arrival announcement

Indicator displays the landing floor, a buzzer sounded

Car fan and light turn-off Automatically

For energy saving, car fan and light turn off automati-cally in case there is no hall call or car call

Automatic Rescue Device

In case of power failure, lift will be sent to the nearest floor by DC power of rechargeable battery, car door open for trapped passenger getting off.

Emergency light

In case of power failure, emergency light on car ceiling turned on automatically

Intercom system

In case of emergency, press the “Emergency button” located on car operating panel to communicate with responsible persons.

Cancel wrong car-call register

Press the wrong called button on COP again to cancel that called register.

Cancel wrong car-call from door hall

Push the wrong hall button again to cancel wrong car-call register.

Anti Nuisance car call protection

Upon activation, all registered car calls canceled, this is used to prevent the car from answering car calls when the number of car call are not correlative with the car load.

Automatic Leveling

In case the load changes significantly when car is landing at the serviced floor, the elevator cabin may some settle. The auto re-leveling feature will automatically adjust the leveling.

Automatic return to main floor

After a waiting period without any call, the elevator will return to the main floor to standby for service commands.

Information display

The operating status information of the elevator is displayed on the screen of the control panel inside the elevator cabin and on the control panels at each floor in Vietnamese, English, or Japanese.

Fire return

The elevator will cancel all remaining calls and return to the designated floor upon receiving a fire alarm signal.

Car Door Anti Stripping Device

The door will be locked to forbid the passenger out in none of landing zone. In door zone, the elevator permit opens landing & car door at the same time.

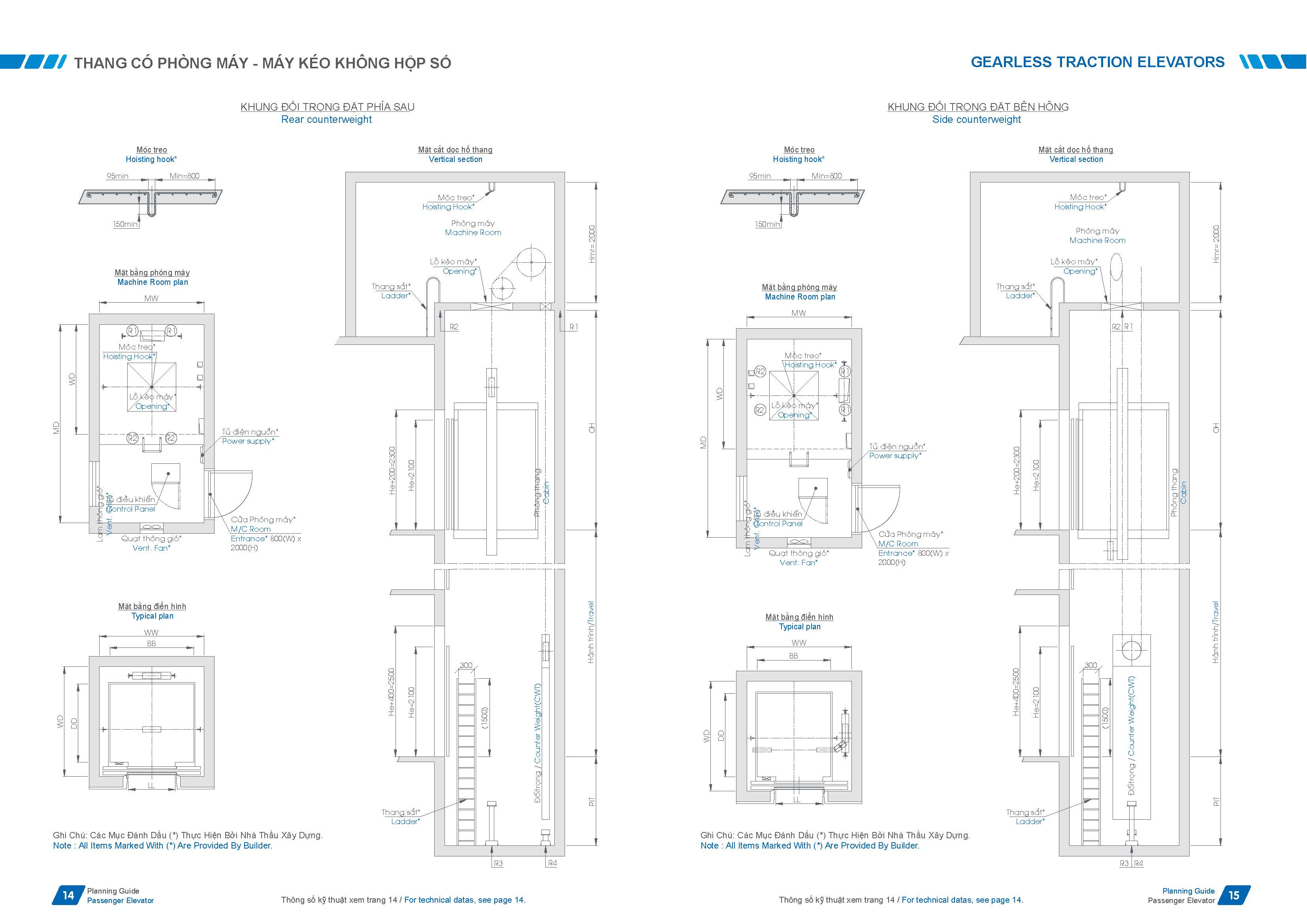

Machine Room

1. Construction of the machine room in accordance with shop drawing provided by thien nam. The walls and the celling shall be finished with waterproof plaster. Door equipped with a lock.

2. Cutting openings tp lift the equipment and roping, wiring from machine room to hoisway. Provition hoist-ing hook.

3. Corridor, stairway, ladder to the machine room should be unpbstructed. Stairs should be equipped with handrails and 700 mm minimum in width.

4. Ventilation: installing ventillation grilles, ventilation fans. The temperature of the machine room shall be below 40oc. The relative humidity should not exceed 90% monthly average and 95% daily average.

5. Lighting: setting natural lighting windows, fluorescent lamps and switch.

6. The machine room power - 01 power supply panel: the power should be three-phases (380v - 50hz) four line and grounding. Power supply voltage variation does not exceed +5%.

Hoistway & Landing Doors

1. Construction of an illuminated, ventilated, and water-proofed elevator hoistway. In accordance with shop drawing provided by thien nam. The folerance of perpendicular line over the whole hoistway height must not exceed +25mm.

2. Provision a ladder to the elevator pit.

3. Cutting openings for installing landing doors, hall buttons and indicators. Finish affter installation.

4. Provision separated beams if two or more connected elevators in one hoistway & safely separated fence between the pits.

5. Water pipes, electrical wires..ect, must not be assembles inside hoistway.

6. Provision intermediate beams if floor height is over 2600 mm.

Special Remarks

1. Provision all electric power for lighting, tools, weld-ing...Ect during installation and test operation.

2. Provision a secured area for storage of elevator equip-pment and material during installation.